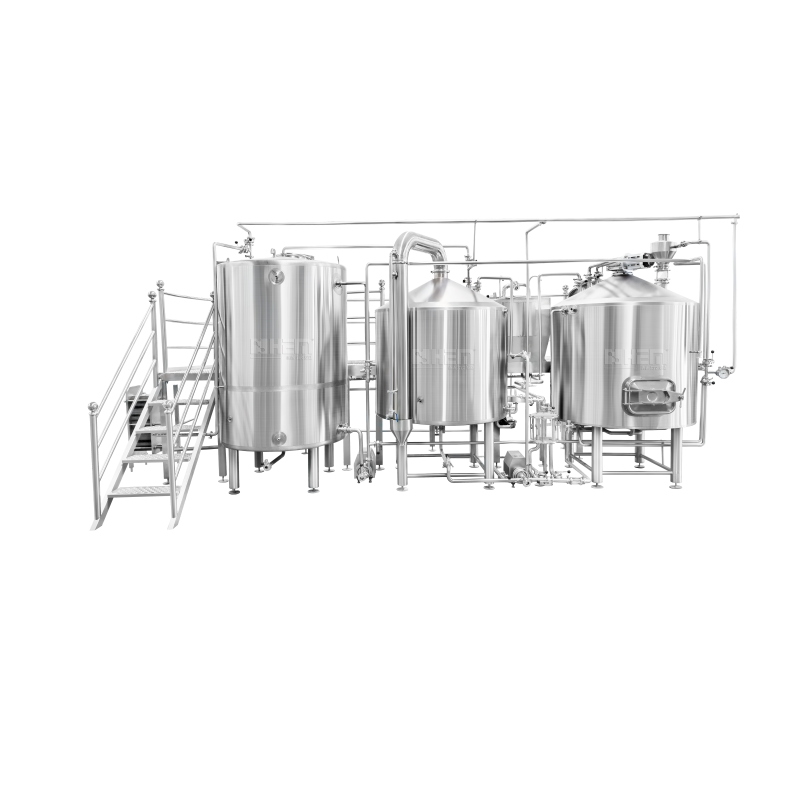

- We plan and design complete breweries, all systems can be designed with the client’s input for a defined process;

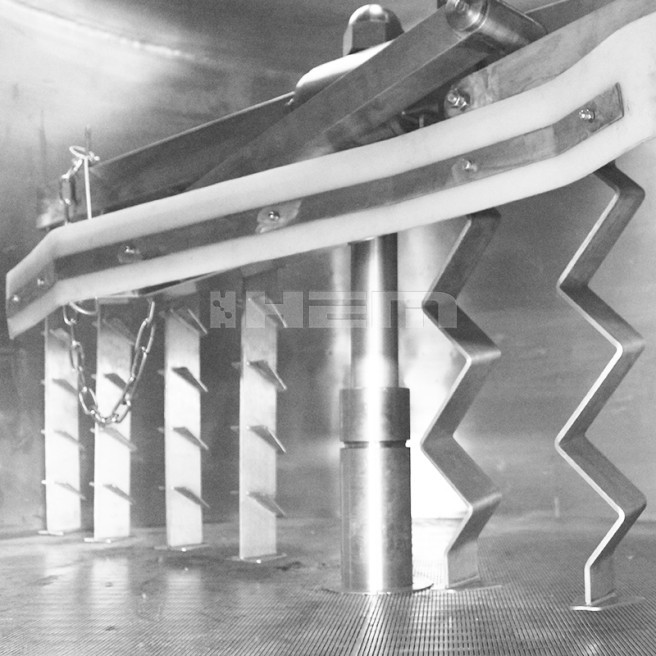

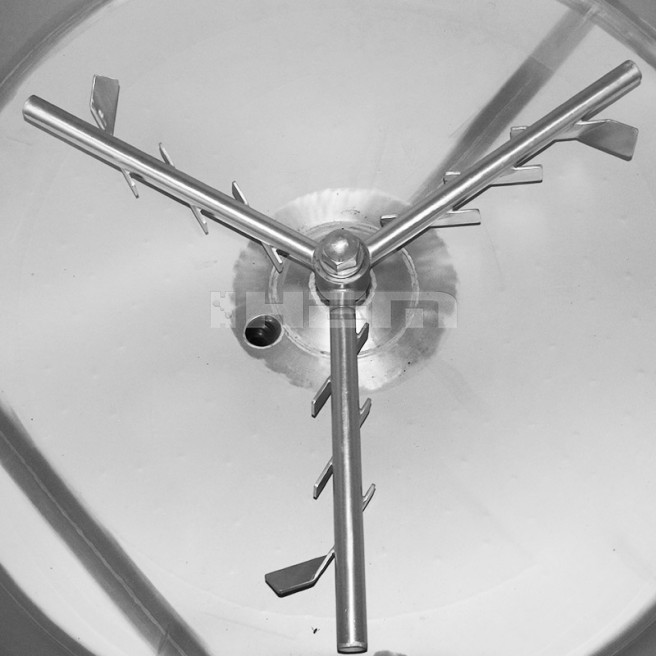

- A variety of different vessel combinations and a number of vessels: multifunctional tanks (mash mixer – lauter, kettle – whirlpool), individual process tanks (mash mixer, lauter, boil kettle, whirlpool, hot/cold water tanks);

- Fully piped and wired, including valves and sensors;

- Integrated pump system;

- CIP system: separated CIP for individual tanks to prevent cross product interference;

- Master brew interface control system (touch screen control panel),

- Staircases and platform combine the vessels in a compact unit, perforated and sectional construction of the walk-on surface ensures protection against slipping;

- Automated lautering, automated water mixing

- High quality insulation effect: Rock wool thickness: 80mm

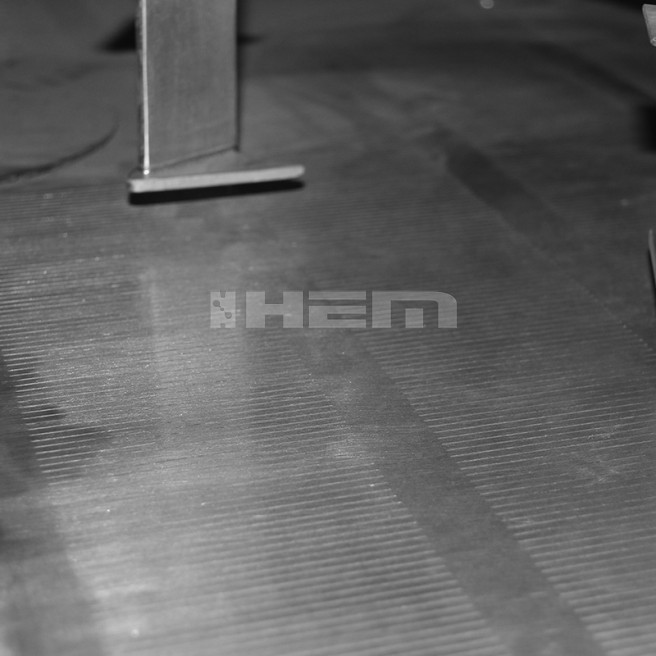

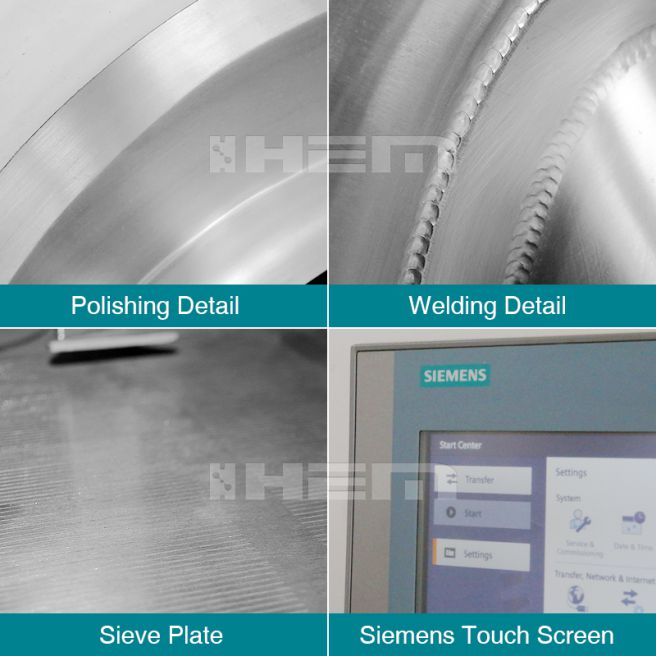

- Beautiful weld and polish: all argon gas protection welding. Polishing precision up to Ra0.6µm

- World’s top brands’ electronic components: siemens PLC and touch screen, Schneider button of circuit breaker, Airtac electromagnetic valves and other pneumatic parts, etc.

- Good abrasion resistance material: inner-Jacket(SUS304)thickness: 3.0mm; external-Jacket thickness: 2.0mm; seal head thickness: 3.0mm

- Fermentation Unit: standard stainless steel conical cylindrical fermentation tanks; tanks quantity is exactly calculated by fermentation cycle for various beers; all manhole, valves, pressure gauges, fittings etc are included

- Bright Tank Unit: standard stainless steel bright tanks for beer maturation, conditioning, service, carbonation; tanks quantity is exactly calculated for various beers and the function; all manhole, valves, stone, gauges, fittings etc are included

- Cooling Unit: insulated glycol water tank with or without copper coil for glycol liquid holding and mixing; efficiency chillers or refrigerators with fryonto supply cooling energy; sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger; all pipes, fitting, insulation materials are included

- Controlling Unit: electrical controlling cabinet with temperature, on-off controlling for brewhouse; electrical controlling cabinet with temperature, on-off controlling for cooling parts; temperature controller, thermocouple, solenoid valves etc are included; PLC with touch screen panel for special request

| Model | BS-1000 |

| Capacity | 1000L/Batch |

| Material | SUS304 |

| Combination method | Mash/Kettle tank, Lauter and whirlpool connection tank |

| Application | Restaurants, bars, hotels, brewery |

| Heating way | Steam heating/Electric heating/Direct fire heating |

| Voltage | AC380/220V, 50/60HZ |

| Power | 15kw |

| Water consumption | 4m3/T |

| Diameter | 1560mm |

| Height | 3000mm |

| Floor area | 10m2 |

| Degree of automation | Semi-automatic/Fully automatic |

| tem | Production capacity | Volume in US Gallon | Heating area | Tank diameter | Height |

| BS-500 | 500L/day | 132 US Gallon | 0.5m2 | 1160mm | 2400mm |

| BS-600 | 600L/day | 158 US Gallon | 0.6m2 | 1160mm | 2500mm |

| BS-700 | 700L/day | 185 US Gallon | 0.7m2 | 1260mm | 2500mm |

| BS-800 | 800L/day | 212 US Gallon | 0.8m2 | 1260mm | 2500mm |

| BS-1000 | 1000L/day | 264 US Gallon | 1.0m2 | 1360mm | 2800mm |

| BS-1500 | 1500L/day | 396 US Gallon | 1.5m2 | 1560mm | 2900mm |

| BS-2000 | 2000L/day | 528 US Gallon | 2.0m2 | 1960mm | 3150mm |

| BS-2500 | 2500L/day | 660 US Gallon | 2.5m2 | 1960mm | 3200mm |

| BS-3000 | 3000L/day | 792 US Gallon | 3.0m2 | 2060mm | 3800mm |

| BS-5000 | 5000L/day | 1320 US Gallon | 5.0m2 | 2260mm | 4400mm |